Let customers speak for us

from 446 reviewsI have ordered several times from the JM Band and I am super happy with the products received. Once upon a time, a package has not arrived on time and although that mistake did not lay with the JM band, they took time, were understanding and friendly through the process. Super customer service! Fine products and very professional staff and work. There I shop again and again :)!

The quality is surprisingly good quality: o)

I got really good service from Thomas when I called. The bracelets are good. Highly recommended.

I was told that it would take a month to produce, but I received the beaches already after 2 weeks!

Fine trade and service

Extremely fast delivery. Ordered 60 bracelets in the afternoon, delivered the next day. Can only recommend this place :)

Thank you. All went well. Fast delivery.

Quick delivery. Single!

Fast delivery and quality as expected - nothing to come after.

Getting the bracelets delivered very quickly and the pressure on it was just like we had hoped.

Thanks for the help ????

The goods are completely as expected and I already received them the day after.

Fast delivery, very good service. Very easy to order.

Fast delivery, good product, this is not the first time I shop!

Fast shipping, excellent material and corresponding to the description. Thank you!!!!!

Fast delivery, really fine product and good price

Who Are You?

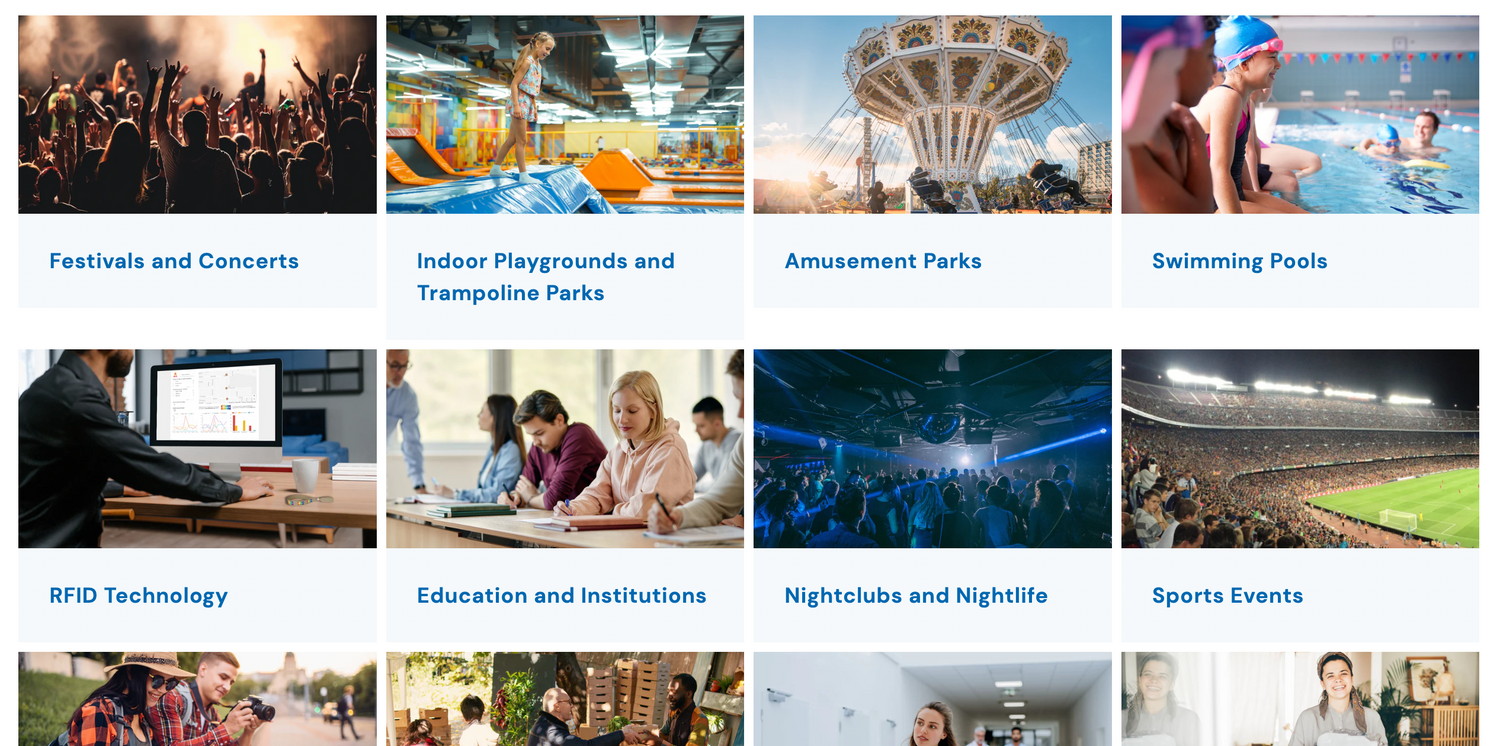

Every day, we are ready to assist and serve customers in various industries. Our goal is to create value for our customers using our unique range of products. Regardless of the industry you are in, you can find relevant solutions below. Or you can explore our extensive product range by navigating through the menu above and discover how our assortment can meet your needs.

We Love Music

That's why we love those of you who support live music, events, concerts, festivals, and gatherings where people come together and enjoy life collectively.

Swimming Pools

Experience safety and comfort with JM Band's products tailored for swimming pools. Whether it's payment RFID wristbands, coins and tokens for lockers, or wristbands for division, we have the solutions to meet your needs.

Learn more about what we can offer you or see a selection of our products below.

Meet Some of Our Customers

See even more customers hereJMband UK - Supplier of Festival Wristbands, Tyvek, Silicone, Fabric and Plastic Wristbands, Cloakroom Tickets, Plastic Cloakroom Tags, Drink and Admission Ticket Rolls, Tokens, Lanyards and Much More

-

Paper, Fabric (Textile), Plastic And Silicone Festival Wristbands

We supply Tyvek paper Wristbands, Fabric Wristbands, Plastic and Silicone wristbands suitable for your festival or special occasion anywhere in UK and Republic of Ireland.

Various colours and designs based on music festival, Dog Shows, fairs, including Christmas and New year themed wristbands are available in ready stock. You also have the option of ordering your own customised design for your special occasion, festival, celebration or event. We have a special online tool to help you design the special festival wristband of your choice and you also have the option to email us your custom design.

Our advanced online designer tool makes it easy to customise both paper wristbands and fabric wristbands on your computer screen. For more complex printing, or in case you already have the design of your customised festival wristband ready you can email it to us.

Festival wristbands are used as an effective means of identification and access. They are a great way to prevent unauthorised access to you festival or event and also to make sure that your guests can enter only the area or areas for which they are authorised. For example during the London new years fireworks display, two types of wristbands are provided. One type of wristband allows helps residents and businesses get into specified surrounding areas without needing proof of address. The ticketed area festival wristband allows authorised ticket holders into the specific viewing area. Our festival wristbands made of paper provide an economical way for access control for an event of one day. In case you want that your wristband should last for a longer period you can use a wristband made of fabric (cloth). -

Tyvek Paper Wristbands

Tyvek paper wristbands, also known as paper wristbands, are a secure, convenient, and affordable method of identifying customers and guests for larger numbers of festivals and events, as well as secure access to amusement parks, museums, water parks, and the like.

Tyvek is a synthetic material manufactured by DuPont, which looks and feels like paper, is breathable, comfortable to wear, lightweight, and very strong. Tyvek paper wristbands are difficult to tear and are durable enough to withstand wear, such as on a dance floor at a club or at an outdoor event. However, they can be easily cut with scissors or a knife.

Water vapor can pass through Tyvek, but liquid water cannot. Tyvek wristbands can be printed with any design or color. You can even print your own special design or festival logo.

We use a special security sealing mechanism on all our Tyvek paper wristbands, making them unusable if anyone attempts to remove them. In addition, all wristbands, including printed Tyvek wristbands, are sequentially numbered, as another security method that allows you to track the consumption of festival bands.

When it comes to Tyvek paper wristbands, customers get a lot for their money, and we deliver it in record time. Customers can choose between printed paper wristbands or plain paper wristbands without print, which we have in stock. A wide range of solid vibrant colors and lively patterns are always available and ready in stock.

We have developed our own system for printing on paper wristbands, and if necessary, we can deliver 100,000 printed paper wristbands as early as the next day. -

Cloakroom Tickets Made of Paper and Cloakroom Numbers Made of Plastic

We offer a wide range of solutions for using a cloakroom with paper cloakroom tickets or plastic cloakroom number tags. Cloakroom paper tickets are offered in 2 parts and 3 parts; both as roll tickets and as booklets. The tickets are marked from 001 to 1000 and are made of high-quality thick paper. Our plastic cloakroom number tags are reusable and environmentally friendly. We can customize your tickets and tags with your own logo and text.

Entrance Tickets, Drink Tickets, and Other Roll Tickets

We also provide entrance tickets in rolls, as well as drink tickets, both of which are delivered in high-quality 'wood-free' 120 gsm paper. Drink and entrance tickets can also be customized to your liking with text and logos.

Lanyards and Key Hangers

There are many combinations and possibilities when it comes to lanyards. We can help you find exactly the key hanger you need for your event. In stock, we have colorful high-quality lanyards that we can send out the same working day you order them. If you need customized key hangers and lanyards, we offer screen printing or digitally printed key hangers and lanyards.

Tokens and Coins

Over the years, we have added a wide range of high-quality tokens and coins to our product range. We provide plastic tokens and metal tokens in various sizes for different uses. Tokens and coins can be customized to our customers' needs, and we also deliver standard tokens and coins that we have in stock for immediate delivery.

-

Printing

Today, speed is very important. We can quickly print many of the products we offer. For items that we cannot print ourselves, we have partnerships with the best manufacturers in this sector and ensure that each produced product meets the quality standard expected by both you and us.

Best Guarantee in Business

JMband guarantees the highest standard of expertise. We offer our customers price guarantee, on-time shipping, quality guarantee, and return guarantee, so you can return products that are not customized. In the case of manufacturing defects in custom products ordered by you, such as paper and woven festival wristbands, printed cloakroom numbers, embossed tokens, etc.; We will offer to reproduce your ordered products according to your exact specifications or a full refund. And it's not just a guarantee, it's our promise to you.

-

Buy Online Tyvek Wristbands, Paper, Fabric (Textile), Plastic, and Silicone Festival Wristbands, Paper Tickets, Plastic Cloakroom Numbers, Lanyards, and More

All our products are of a high quality in vivid colours and at a very good price. Backed by 25 years of experience. So what are you waiting for? Order Now and see the difference. We are very sure that you'll be delighted with the quality you get for the money.

We will ship your order from Aarhus in Denmark and all our orders will be dispatched within 24 hours for items in stock.

We deliver anywhere in UK, Jersey, Guernsey, and Republic of Ireland. Normally the transit time is about 2 days if your delivery address is in or not far from major cities in the UK and Republic of Ireland like London, Cardiff, Belfast, Birmingham, Calgary, Cork, Coventry, Dublin, Glasgow, Manchester, Newcastle, Nottingham, Leeds, Liverpool, etc. Delivery to remote areas in the UK may take an extra day or two. -

Watch Our Story - Who We Are And What We Can Do For You

With more than 30 years of experience in admission control and marking products, we can help you find the right solution for the right price and deliver it the way you want it. We can also supply you products with the exact design and specifications as per your choice. We achieve this by selecting impeccable quality of materials and ensure that each item manufactured is a hallmark of quality.

Our customers know that they can rely on JM Band. If we can't do it, we say "sorry we can't take the job" if we can do it, we do it right and on time.

Try us and see for yourself. We are here for you.